304 stainless steel locker for meat processing factory worker

With our excellent management, powerful technical capability and strict high-quality regulate technique, we continue on to provide our consumers with dependable excellent, reasonable rates and outstanding services. We goal at becoming certainly one of your most trustworthy partners and earning your satisfaction for 304 stainless steel locker for meat processing factory worker, The continual availability of high grade solutions in combination with our excellent pre- and after-sales services ensures strong competitiveness in an increasingly globalized market place.

With our excellent management, powerful technical capability and strict high-quality regulate technique, we continue on to provide our consumers with dependable excellent, reasonable rates and outstanding services. We goal at becoming certainly one of your most trustworthy partners and earning your satisfaction for locker for meat processing factory worker, We are going to do our utmost to cooperate & satisfied with you relying on top-grade quality and competitive price and best after service ,sincerely look forward to cooperating with you and make achievements in the future!

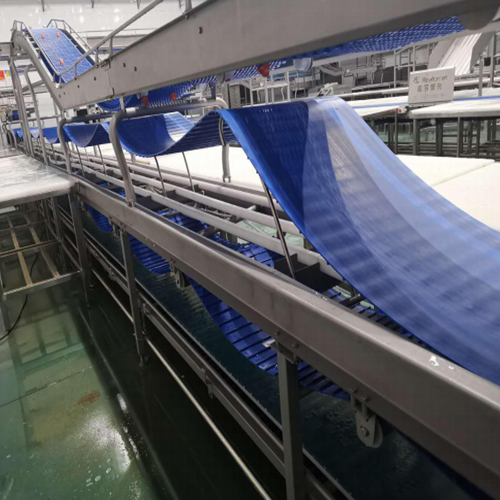

Product in locker room: Locker, Changing shoe stools, hangers, changing shoe cabinets and so on.

1, general food processing plant staff changing procedures: into the workshop after the replacement of sandals into the workshop special slippers – wear inner hat or hair net – wear outer hat – wear a mask – wear work clothes jacket – wear work library – put on water shoes – wash hands disinfection procedures into the workshop.

2. Locker room design varies according to the number of your staff and different hygiene standards. The general idea is to avoid cross-contamination, such as

1) changing order from top to bottom, from inside to outside, finally wear boots, is more bacteria on the feet, if the first change will pollute the work clothes;

2) Storage of different items in different areas, such as slippers, water boots, work clothes, casual clothes must be separated to avoid cross-pollution, so generally at least two rooms: shoe changing room, changing clothes, casual clothes storage cabinet, work clothes hanging clothes rack, slippers, slippers, water boots different shoe rack storage;

3) The logo should be perfect. The changing process and photo logo of entering the locker room should be completed. The slipper area, water boots area, casual wear area and work clothes area should be marked.

4) Equipped with necessary sanitation facilities, including anti-fly mouse board, anti-fly lamp, ventilation fan, sterilization UV lamp or ozone, hair removal and other impurities of the air shower or sticky hair device, hand dryer, hand disinfection and water boot disinfection facilities, etc.

Parameters

|

Product name |

304 stainless steel locker |

| Product size | 900*380*1800mm/1000*450*1800/1200*380*1800mm/customized |

| Material | 304 stainless steel |

| Thickness | 0.8mm/1.0mm/1.2mm |

Details Picture

304 food grade stainless steel locker, in line with food factory health and safety requirements, and durable

304 food grade stainless steel locker, in line with food factory health and safety requirements, and durable