Meat Processing Equipment Factory – Carcass splitting circular machine – Bomeida

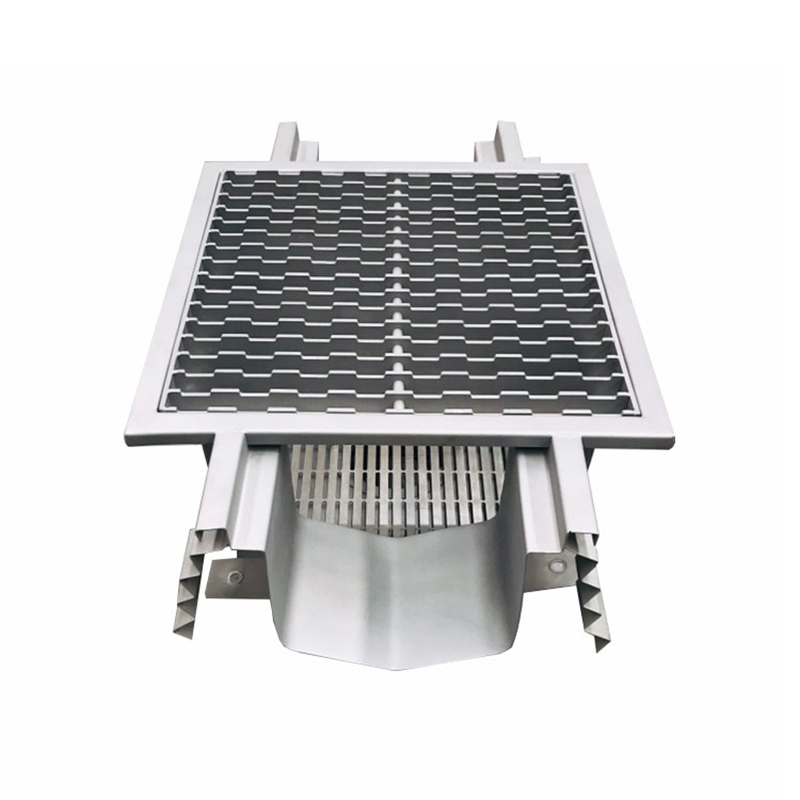

Meat Processing Equipment Factory – Carcass splitting circular machine – Bomeida Detail:

Features

1、The whole machine is made of SUS304 stainless steel, which can meet the requirements of food hygiene.

2、Imported German saw blade, smooth operation, sharp edge will not produce bone fragments and other debris, less loss. More than 1 million cutting life, no maintenance.

3、The height can be adjusted and can be rotated for wider adaptability. Set up the ground installation device to install more firmly. Productpositioning sensor, safer and easier to operate.

4、The head has the function of 180 degree rotation, which makes the equipment maintenance and repair more convenient. The saw blade is equipped with safety protection device to ensure safe production.

5. Laser positioning, more accurate cutting

6. It is provided with circuit breaker, magnetic contactor, start and stop buttons and emergency stop buttons

Parameters

| Product Name | Carcass Splitting Circular Machine |

| Size | 1435×775×1675mm |

| Power | 1.5kw |

| Speed | 48r/min |

| Saw Diameter | 750mm |

| Net Weight | 256KG |

| Package size | 1600*855*1540mm |

Details Picture

Product detail pictures:

Related Product Guide:

To be a result of ours specialty and service consciousness, our company has won a superb reputation between customers all around the environment for Meat Processing Equipment Factory – Carcass splitting circular machine – Bomeida, The product will supply to all over the world, such as: Ecuador, Jersey, Poland, By adhering to the principle of "human oriented, winning by quality", our company sincerely welcomes merchants from at home and abroad to visit us, talk business with us and jointly create a brilliant future.

The customer service staff is very patient and has a positive and progressive attitude to our interest, so that we can have a comprehensive understanding of the product and finally we reached an agreement, thanks!