Industrial Sausage Filling Machine

Introduction:

The control system of Vacuum Filler is designed with independent R&D CNC system, 8.4-inch true color LCD, special industrial keyboard, waterproof front panel and humanized design control

interface, intuitive and clear. Vacuum Filler is built with a combination of Japan servo motor, German decelerator and high-quality vacuum pump. This machine is used for quantitative filling and

high-speed twisting in vacuum. preventing fat oxidation and protein hydrolysate, reducing the amount of bacteria thus extending the shelf life of product.

Hopper Volume: 160L 240L

Application: natural casing. collagen casing and smoke casing twisting.

Dual filling tubes and Vacuum Filler can be combined with full-automatic clipper machine.

Twisting speed:640pcs/min (e.g., 6g/pc) (Stepless speed regulating available).

Drive mode. AC servo motor.

Twisting tube size: Ф10.Ф12.Ф14, Ф16. Ф19, Ф22 (optional 3)

Clipping and filling tube: Ф16.Ф22.Ф28.Ф30.Ф40 (optional 3)

Impeller, blade and pump body is designed with high hardness, high wear-resisting stainless steel and the master body adopts 304 stainless steel.

Parameter:

| Model | Quantitative Range | PowerKw | Filling Twisting speed | Hopper Volume | Voltage | WeightKg | Sizemm |

| BMD3000 | 6-9999 | 7.9 | 0-600/min | 160 | 380V | 590 | 1350*861*1710 |

| BMD3500 | 6-9999 | 8.35 | 0-600/min | 240 | 380V | 630 | 2450*1180*1800 |

| BMD5000 | 6-9999 | 9.2 | 0-600/min | 240 | 380V | 750 | 2450*1180*1800 |

| BMD7500 | 6-9999 | 10 | 0-600/min | 240 | 380v | 830 | 2450*1180*1800 |

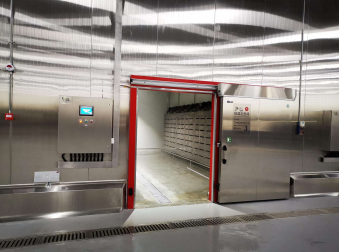

Picture: